Machine Safety Certification for all levels of compliance

All machinery put into use in the countries of the EU must comply with a broad range of directives. Awareness and understanding of this complex area is an essential prerequisite to implementing best practise in machine safety.

Certification Services

Injection Moulding Machines

Plastic & Rubber moulding machines fall within the new ANNEX 1 of EU Machinery Regulation [2023/1230] as High-Risk Machinery Products, therefore require the inclusion of a Notified Body, to complete the necessary compliance procedures for CE certification.

A Notified Body [CEAL] can carry out a prescribed amount of test procedures, evaluate the conclusions and issue an EC Type Examination Certificate, which allows the manufacturer, or their Authorised Representative to issue the Declaration of Conformity.

These evaluation and validation procedures are mandatory prior to the product/machine being placed on the market or put into service.

Mobile Elevation Work Platforms

MEWPs which have a design elevating height of more than 3 metres vertically, require the inclusion of a Notified Body to complete the necessary mandatory compliance procedures for CE certification.

Such MEWPs are within the scope of ANNEX 1 of the Regulation as High-Risk Machinery Products, therefore, extensive tests and verification programmes are required to be carried out, before the manufacturer can issue a Declaration of Conformity.

CEAL, as a Notified Body, have extensive experience in assisting manufacturers and users, to obtain CE certification, under ANNEX 1 of EU Machinery Regulation 2023/1230.

Safety Devices for Protection

Machinery automation and the increased introduction of Artificial Intelligence systems, underpin the EU Commissions requirement, that such systems, included within safety related functions, be examined, evaluated and certified by a Notified Body.

The procedures are comprehensive, however, involve the designer/manufacturer, therefore requires a combined & positive attitude to validation.

CEAL, have a long history with automation designers and manufacturers and can offer a Notified Body service, with many years’ experiences of validation around Artificial Intelligence (AI).

Power Operated Safety Guards

Included within ANNEX 1 of the new EU Machinery Regulation, 2023/1230 as High-Risk Machinery Products, can be found as a component part of assemblies such as Press Brakes, Moulding machinery, Automatic/Robotic CNC assemblies, etc.

A Notified Body is required to carry out specific test procedures so that an EC Type Examination Certificate can be issued.

CEAL, a Notified Body, have the specialised & calibrated equipment that is required for the testing programme.

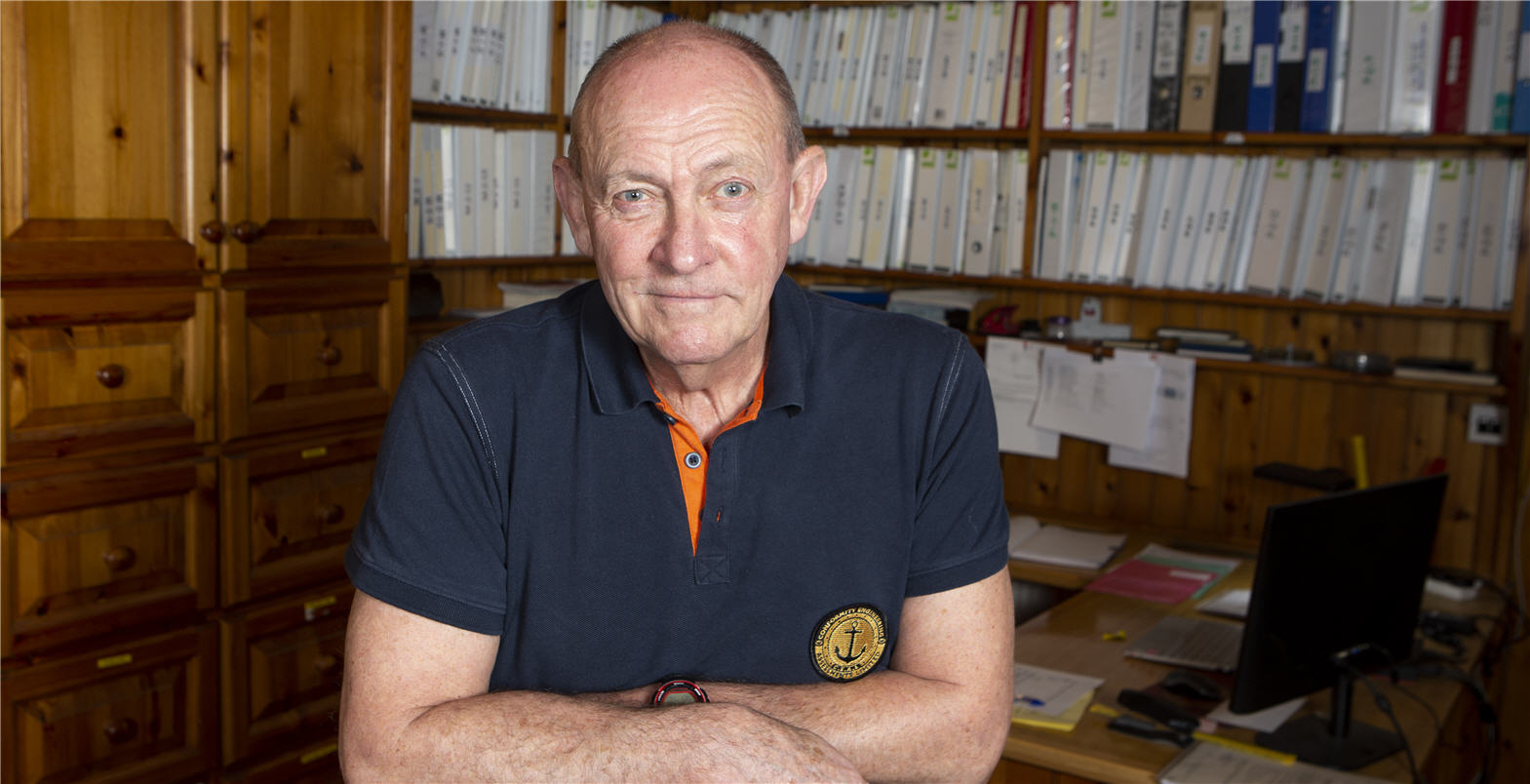

Power Take Off Equipment

Whilst normally associated with agricultural and construction plant, these transmission devices can be found in many other installations, i.e., water, hydraulic, or electrical generation plants.

Included within the scope of the EU Regulation, 2023/1230, ANNEX 1, as High-Risk Machinery Products, they require the inclusion of a Notified Body, to evaluate, test, verify and certify the assemblies. The guards associated with PTO shafts are considered as a separate component and are included within ANNEX 1 as a separate device, comprised within the assembly. CEAL are accredited to evaluate and certify both components.

Falling Objects Protection Structures

Normally associated with just agricultural machines, these protective structures are commonly found in construction, warehouse and mining machinery.

Included within the scope of ANNEX 1 of the new EU Machinery Regulation, 2023/1230, they are considered High Risk Machinery Products and therefore require the input of a Notified Body, to complete the appropriate EU Examination certification.

Safety Devices for Detection

There are many types of safety devices, which we shall describe later in SAFETY DEVICES II. As a Notified Body accredited as being responsible for the correct CE evaluation, test and certification of safety devices designed to detect the presence of persons, we pride ourselves on the accuracy and detail in the evaluation process.

Such safety devices include: Laser scanners, light curtains, pressure sensitive mats, etc, each of which have a comprehensive list of tests, examinations and validation procedures that must be completed prior to the issue of an EC Type Examination Certificate by an accredited Notified Body such as CEAL.

General

CEAL, have for many years, carried out machinery audits, for Clients, whose machinery assemblies may fall within the following headings; Existing machinery that has been operating for many years, however there is now a question as to its safety suitability regarding the type and design of safety devices. Modified machinery, where the basic function has changed or there is a requirement to upgrade safety systems. Assemblies involved in personal injuries. Validation of safety systems after repair or maintenance work. New installation of several machines within an assembly of machinery.

Contact us to discuss your situation and we can arrange to view your drawings or visit your site for an appraisal of the installation(s).

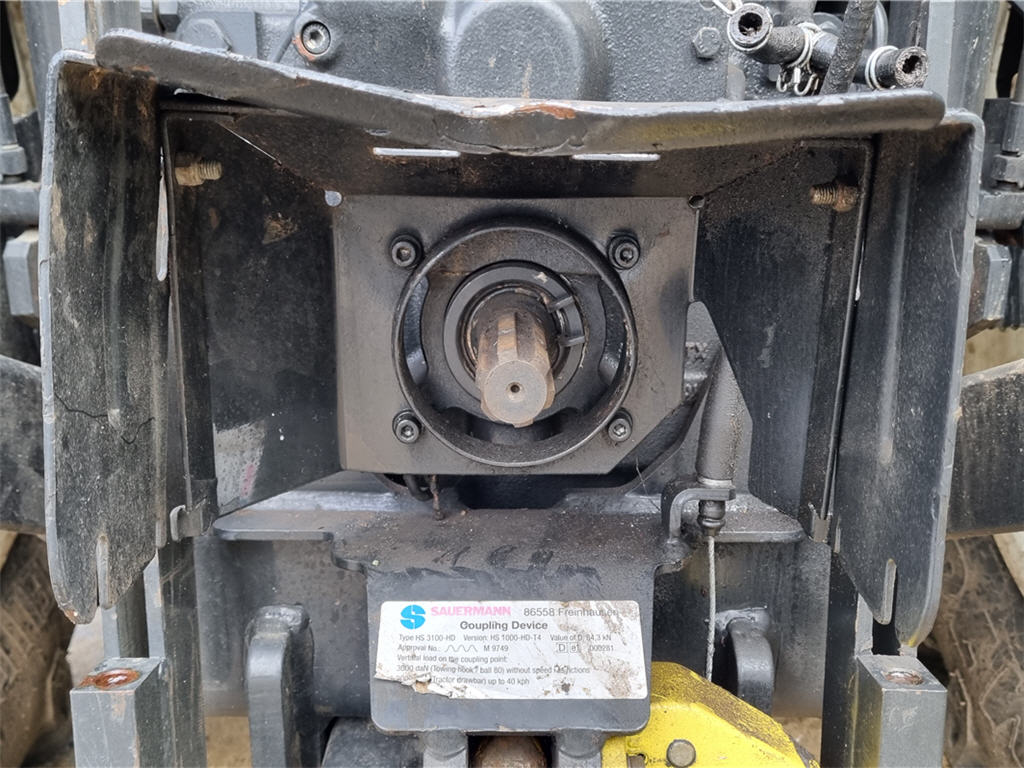

Training

CEAL have developed a training course for Technicians & Engineers, which will assist them to understand and implement machine assembly safety designs and procedures based upon the legal requirements and the philosophy of EN ISO 13849-1:2015.

In addition to meeting the requirements of the harmonised standard, there is also a critical component of validation, which is enshrined within EN ISO 13849-2:2012. This latter requirement can on occasions be missed, which in effect negatives the purpose of the design and installation stage of Part 1 of the Standard. Our training also includes the use of different safety related standards such as EN ISO 13849-1:2015, EN ISO 60201:2021 & EN ISO 62046:2018.